Sustainability storytelling

〰️

Sustainability storytelling 〰️

Introduction

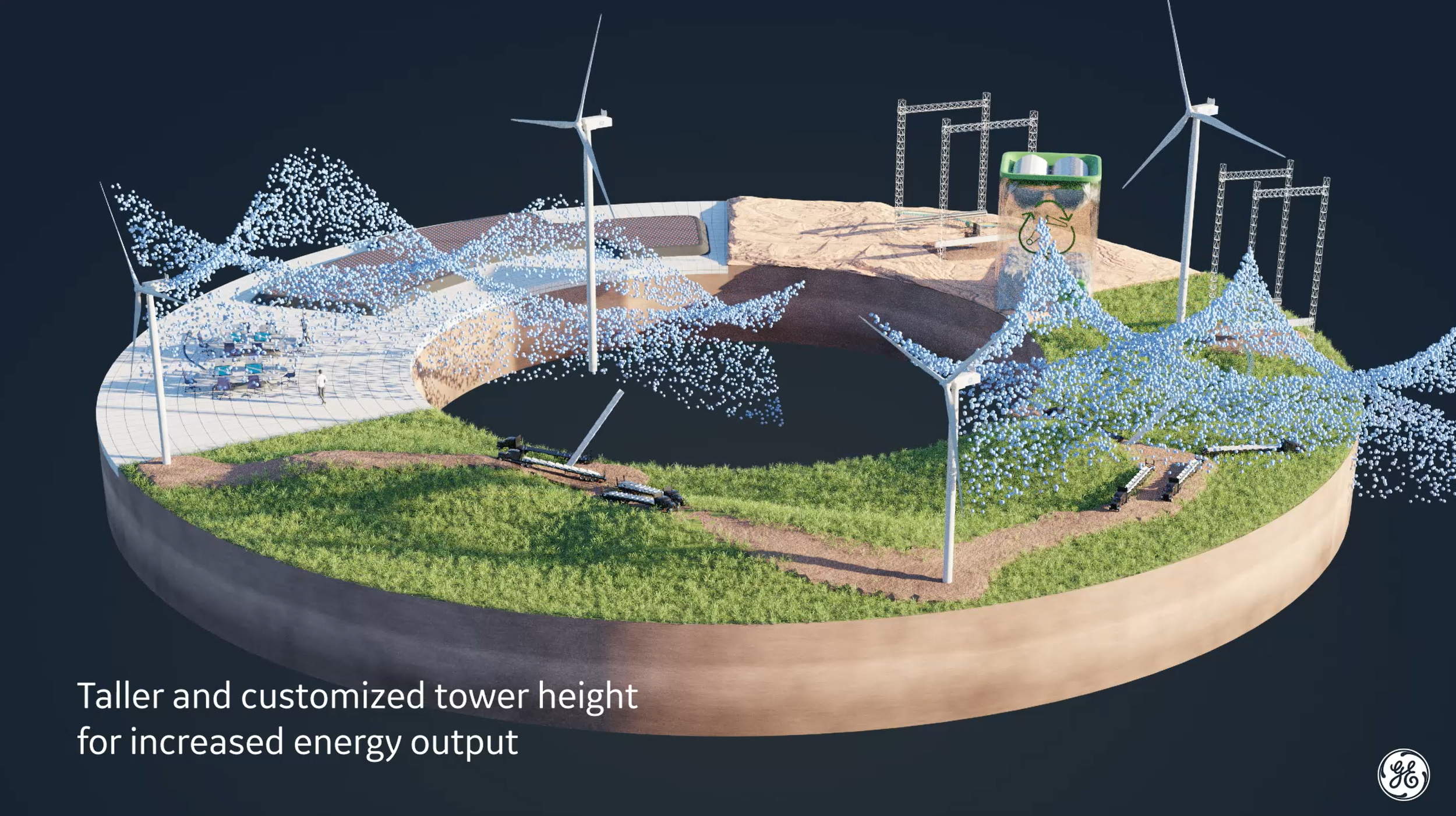

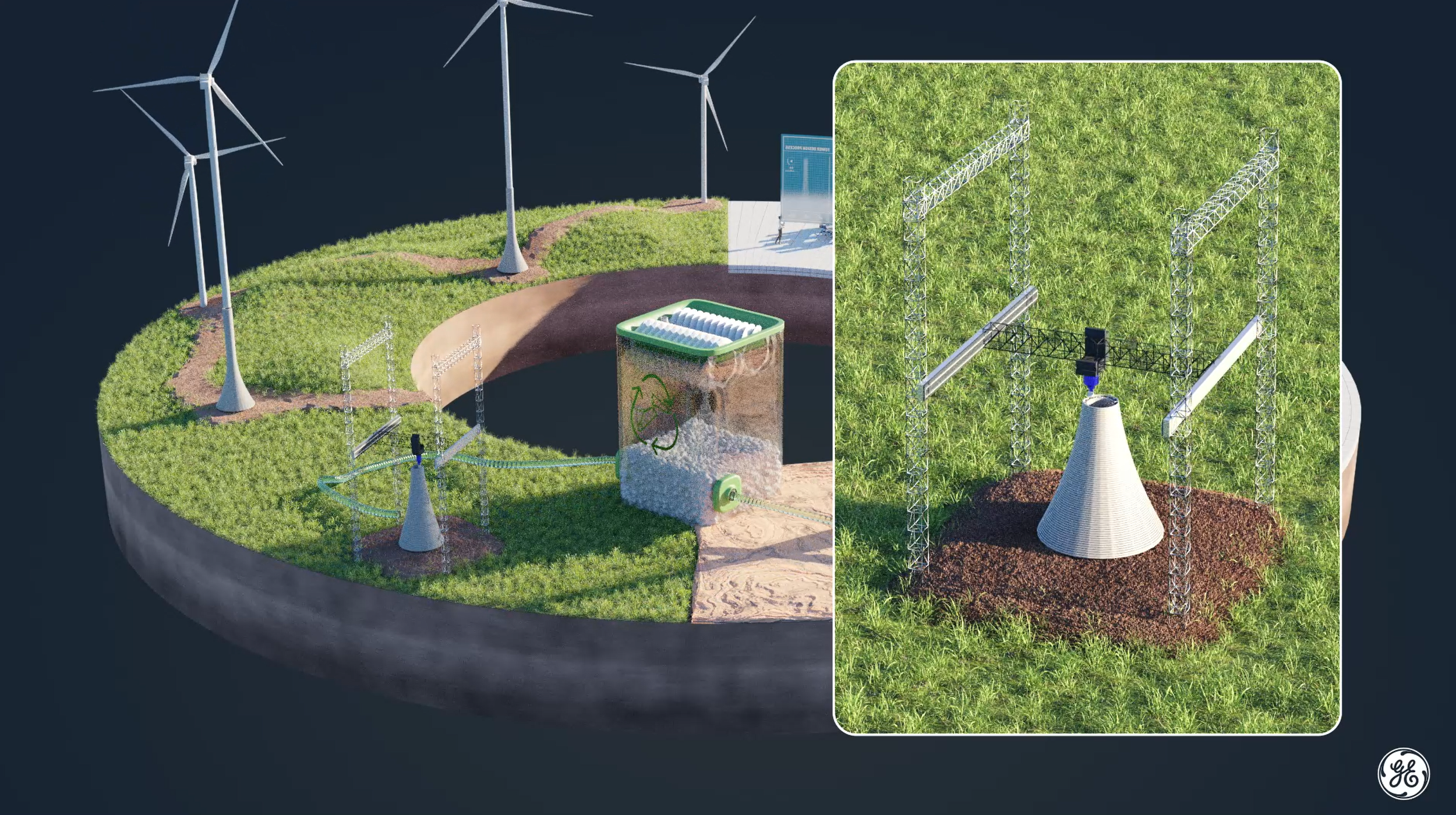

This case focuses on one of many solutions KIRT x THOMSEN has delivered during our longstanding collaboration with GE Renewable Energy. A world leader within Renewable Energy Semiconductor Manufacturing. Combining onshore and offshore wind, blades, hydro, storage, utility-scale solar, and grid solutions as well as hybrid renewables and digital services offerings.

Challenge

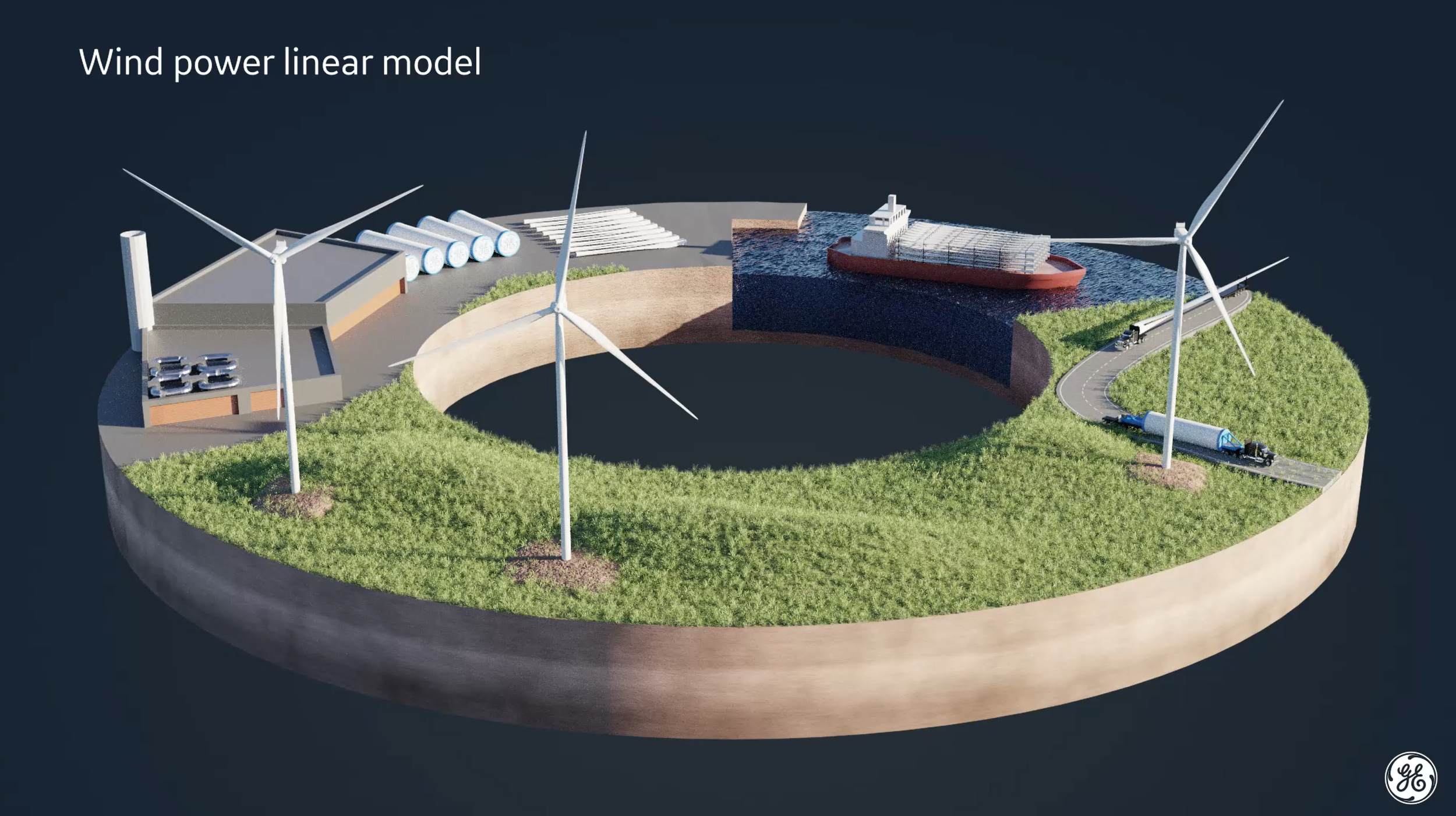

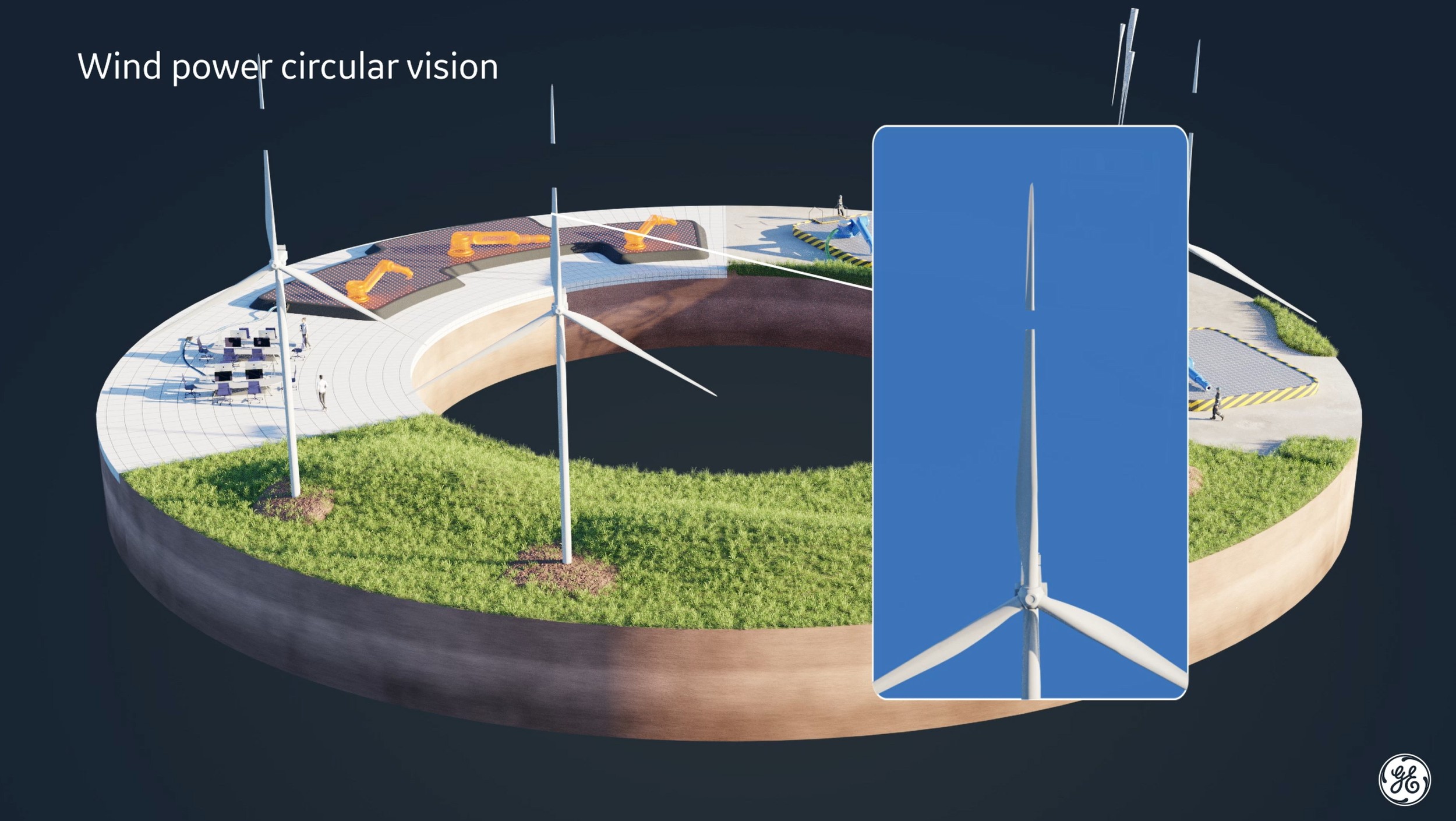

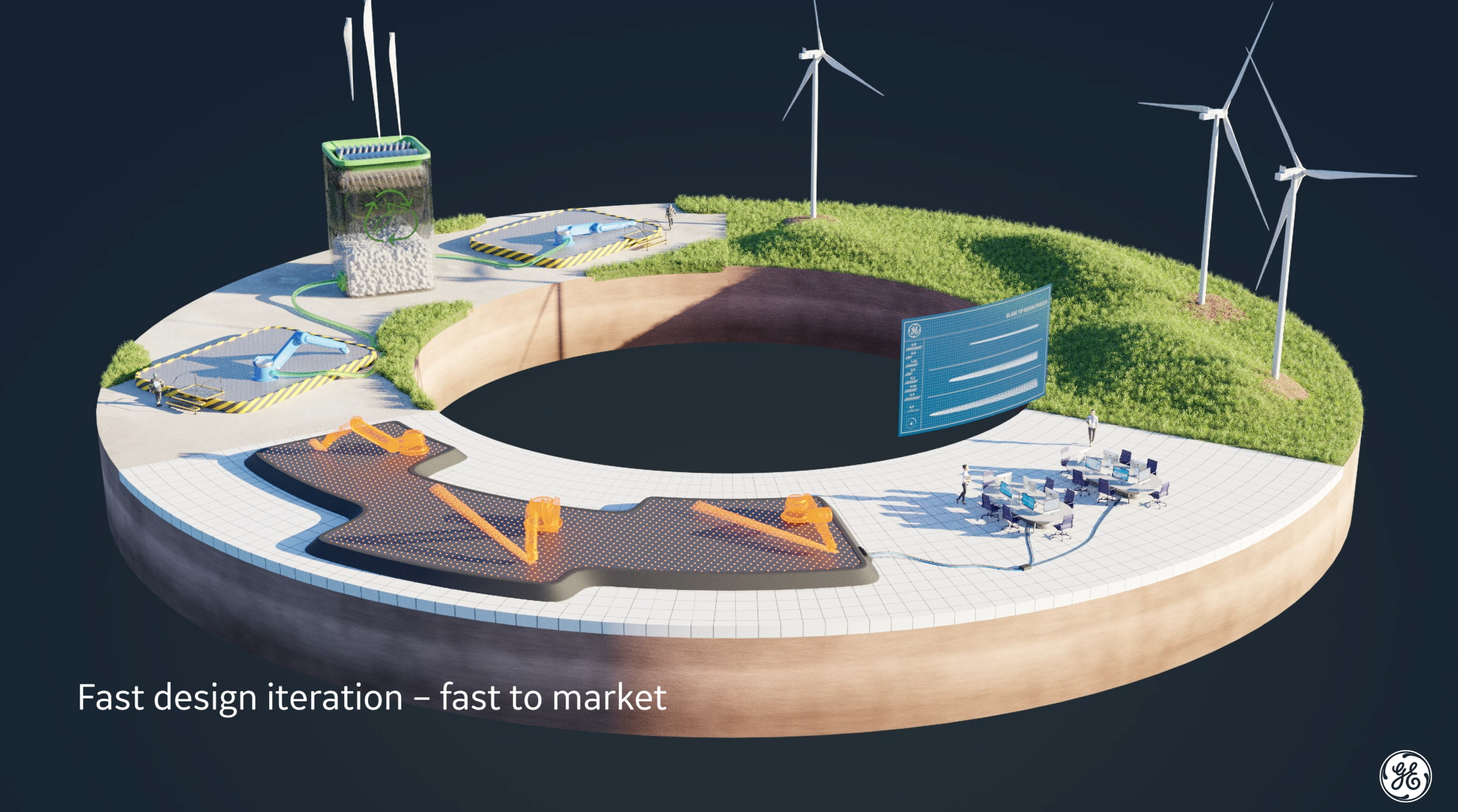

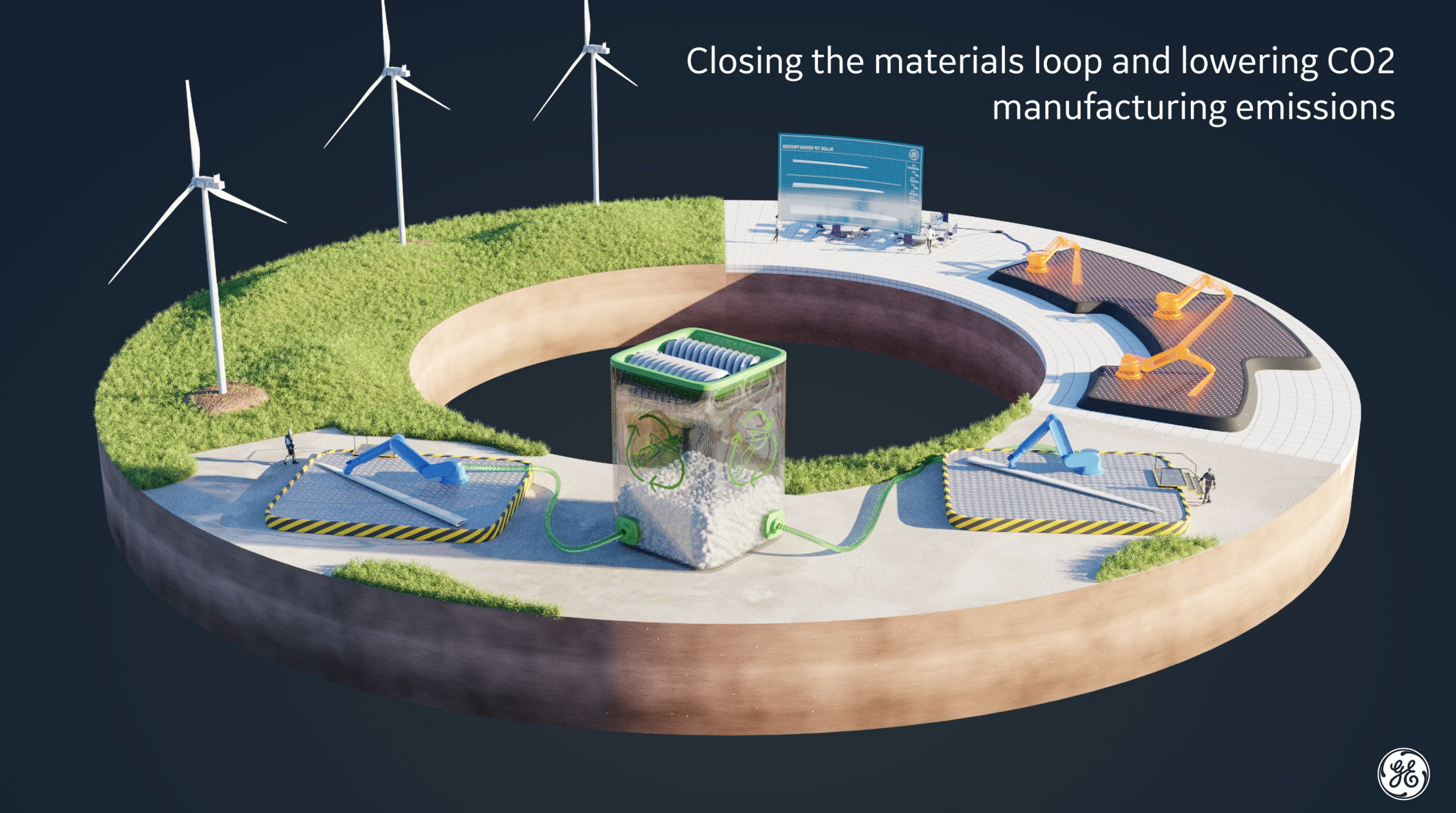

The requirements for this project were to help GE with their communication about what is additive manufacturing and the value proposition across the entire value chain involved in wind-turbine design and construction, and why it is sustainable. In short, additive manufacturing or additive layer, manufacturing is the industrial production name for 3D printing, a computer-controlled process that creates three-dimensional objects by depositing materials, usually in layers.

With a primary focus on external communication, the objective was to create visuals and animations for storytelling for investors, developers, clients, and media, in a detailed manner but without revealing critical competitor-sensitive information about GE’s technology.

Blade tip printTower print

Solution

In close dialog with GE’s communications team, we created a series of animations and videos that can be used across all platforms and support GE’s sustainability storytelling and the complex technology of additive manufacturing in an easy for all types of external stakeholders to understand.

Result

We succeeded in delivering a solution that meets all requirements for the GE needed end-product, in a work process involving different internal stakeholders from GE’s innovation to communications teams.

To learn more, feel free to reach out to CEO of KIRT x THOMSEN Rune Kirt at rune@kirt-thomsen.com.